When you think of recycling, it’s likely you think in terms of sustainability and saving the planet. But when it comes to pallets and the supply chain, recycling can also mean saving your business money.

The global supply chain moves on pallets – mostly on wooden pallets. In fact, more than 90% of the two million pallets used every day in the United States are constructed from wood. These workhorses take a beating, no doubt, but it’s not necessary to write off a wood pallet once it’s used – even if it takes on a little damage. A study by Virginia Tech on the disposal of wood pallets at landfill sites reveal that 95% of wooden pallets are being recycled.

It might seem convenient to toss out that used pallet, but by keeping pallets in circulation and recycling them for future uses, you’re saving trees and saving money. The cost of routinely purchasing new pallets can escalate quickly. But a used or recycled pallet can save your business as much as 75% over buying a new wood pallet. And because they’re thoroughly inspected, these recycled pallets offer all the structural integrity of a new pallet.

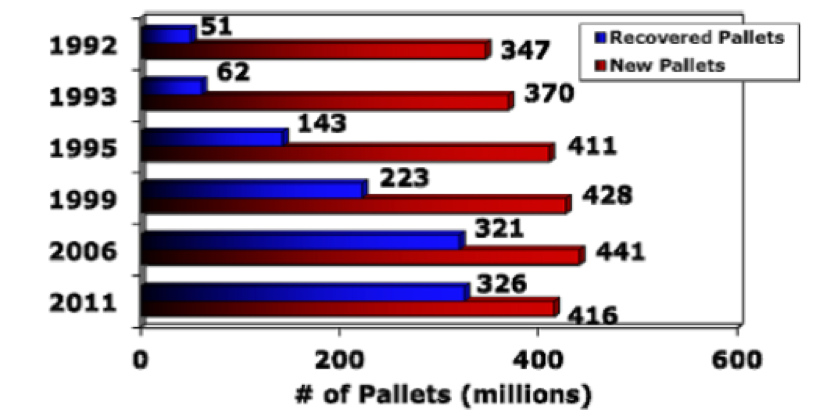

The idea of incorporating recycled pallets into the supply chain has certainly gained traction in recent years. As this graph illustrates, the number of new pallets in circulation has remained quite steady, while recycled pallets have increased more than 600% since 1992.

Though the “green” aspects of using recycled pallets make for good PR and offer their own support for recycling pallets, the truth is that many businesses are first and foremost interested in cutting back on unnecessary costs. Fortunately, with the right partner, this is easily possible.

A pallet management partner can help keep your flow of pallets moving – so you always have the right amount of pallets when and where you need them. The right partner will process all your wood pallets, which includes inspection of each pallet after use. Those deemed fit for reuse are put back into circulation. Some with minimal damage can be repaired and then placed back into the market. Those beyond repair will either be salvaged for other uses, such as repairing the aforementioned damaged pallets, or ground to become mulch or other wooden by-products.

The key here is that you’re not purchasing expensive new pallets when you don’t need to do so. But there are additional potential advantages and cost-savings to recycling pallets through a pallet management partner.

For example, Relogistics recently provided a customer’s new distribution center with ready-to-go pallets in exchange for a certain number of surplus pallets at a later date. This eliminated the need for the customer to come out of pocket for the purchases and ensured a smooth transition before the facility opened, all while taking the sustainable route of using recycled pallets.

Whether purchasing ready-to-go recycled pallets or selling surplus pallets to be recycled, Relogistics can develop a cost-saving program to meet your specific needs. Pallet repair can not only add up to substantial savings on your bottom line, but helps encourage and support sustainability efforts around the globe. Pallet recycling means doing good for your business and for the environment.